Manufacturing (Consulting)

MXGlobal has one of the most experienced teams in the manufacturing industry. Your consulting experience will be thorough with a team that manages projects across Lean, ISO, Supply Chain Management, Quality Improvement and Metallurgy. Your organization benefits from our consultants' experiences in the industry as well as consulting experience within the industry.

Lean Consulting

Lean Consulting

About Lean

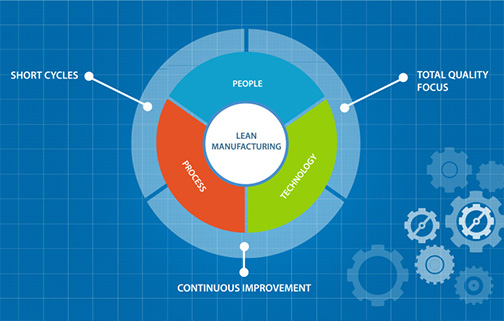

Lean is a beneficial culture that utilizes a framework of concepts and methods to ensure a company is "healthy" and efficient. The principles of Lean are consistent throughout industries, but the practice will vary depending on the company's service/product/culture, industry and marketplace. The Lean discipline originated in manufacturing, thus the nomenclature is often seen as Lean Manufacturing but truly applies across all industries and organizations. The goal is to ensure the highest quality of product/service while minimizing the cost by ensuring that waste (product or process) is eliminated, i.e., Waste Reduction leads to Cost Reduction. Time to market is an extremely important objective through the Lean process as this is a significant factor that has an affect on cost. Consensus throughout the organization and the involvement/participation of each and every team member is an important pillar to build on for success. Historically, Toyota is well know for its Lean Manufacturing practices and had two pillars: Jidoka (Stop at abnormalities) and Just In Time (Pull System and Continous Flow). Stability of this process is attained by i) Leveling Production, ensuring that the process is as repetitive as possible, ii) Standardization of the Work, ensuring that all team members can see when a product or process is failing, and iii) Continuous Improvement, identify the problem, fix it, learn.

Benefits of Lean

- Management Focus: efficient processes / procedures allow team members to be more vested in the process, creating an environment with management focusing on client needs and focused key performance indicators (KPIs). Non-conforming processes and procedures will be evident to managers and team members alike, addressing the issues in a more timely manner.

- Problem Resolution: unresolved issues are continually addressed by cross-departments and cross-functional team members, ensuring that problems are resolved in a timely and focused manner.

- Safety: Efficient and predictable work spaces, significantly reduce injury, potential injury and allow team members to focus on process instead of distractions from unsafe environments.

- Quality Improvement: tracking challenges and addressing process / procedures to address challenges, identifies key places of challenges and corrects the situation.

- Efficiency Improvement: analysis of every task throughout process, creating repeatable, predictable procedures to ensure higher throughput with minimal errors.

- Workforce Allocation: efficient processes / procedures typically reduce human resources dedicated to tasks. Human resources trained and reallocated to higher value tasks, resulting in higher quality and greater output.

- Space Utilization: efficient processes typically lead to lower space requirements, allowing the organization to benefit from lower premise expenses and/or providing needed room for growth.

Lean Implementation

MXGlobal provides the team best suited for the review and implementation of the Lean process in your organization. Fundamentally, there are four steps, i.e., i) Observing your process with focuses on the seven wastes (transportation, inventory, motion, waiting, over processing, over production and defects ii) Involving team members with a focus on Quality and Time iii) Metrics and Tracking iv) Attempt Implementation of proposed solutions.

ISO Certification

ISO Certification

Like a symphony, it takes a lot of people working together to develop a standard. - ISO

ISO is an independent, non-governmental international organization with a membership of 162 national standards bodies. Through its members, it brings together experts to share knowledge and develop voluntary, consensus-based, market relevant International Standards that support innovation and provide solutions to global challenges. ISO creates documents that provide requirements, specifications, guidelines or characteristics that can be used consistently to ensure that materials, products, processes and services are fit for their purpose. Bringing real and measurable benefits to almost every sector imagineable, standards underpin the technology that we rely on and ensure the quality that we expect. MXGlobal provides expert teams that will provide the support and documentation to meet an ISO audit. The process includes understanding your organization's process/procedures, review of each process individually and the related audit items for each process, collaborating with your organization's team members to align processes with audit performances and ensure organizations processes/procedures and related documentation is ready for ISO compliance audit as well as policies and procedures for ongoing processes, ensuring that your organization is managed in an efficient and ISO compliant fashion.

Supply Chain Management

Supply Chain Management

A supply chain is the connected network of individuals, organizations, resources, activities and technologies involved in the manufacture and sale of a product or service. A supply chain starts with the delivery of raw material from a supplier to a manufacturer, and ends with the delivery of the finished product or service to the end consumer. Supply Chain Management (SCM) oversees each touch point of a company's product or service, from initial creation to final sale. With so many places along the supply chain that can add value through efficiencies or lose value through increased expenses, proper SCM can increase revenues, decrease costs and impact a company's bottom line. Supply chain management (SCM) is the active streamlining of a business' supply-side activities to maximize customer value and gain a competitive advantage in the marketplace. SCM represents an effort by suppliers to develop and implement supply chains that are as efficient and economical as possible. Supply chains cover everything from production, to product development, to the information systems needed to direct these undertakings. Typically, SCM attempts to centrally control or link the production, shipment and distribution of a product. By managing the supply chain, companies are able to cut excess costs and deliver products to the consumer faster. This is done by keeping tighter control of internal inventories, internal production, distribution, sales and the inventories of company vendors. SCM is based on the idea that nearly every product that comes to market results from the efforts of various organizations that make up a supply chain. Although supply chains have existed for ages, most companies have only recently paid attention to them as a value-add to their operations. MXGlobal will provide expert, experienced consultants to ensure your organization's supply chain management is efficient, effective and transparent throughout the organization.

Quality Improvement

Quality Improvement

Quality comes not from inspection, but from improvement of the production process - W. Edwards Deming

Quality improvement (QI) is a systematic, formal approach to the analysis of practice performance and efforts to improve performance. A variety of approaches exist. The importance of fully committing to a quality process and practice cannot be understated. Understanding and properly implementing QI is essential to a well-functioning organization, and is nonnegotiable for any business interested in improving efficiency.

QI Fundamentals

- Establish a culture of quality. Processes and procedures should support and be integrated with your QI efforts. This “QI culture” looks different for every business, but may include establishing dedicated QI teams, holding regular QI meetings, or creating policies around your QI goals.

- Determine and prioritize potential areas for improvement. Leverage existing company information regarding quality. Research industry quality metrics to establish a baseline. Determine quality goals and related financial impact.

- Collect and analyze data. Data collection and analysis lie at the heart of quality improvement. Data will help to understand how well processes/procedures are working, identify potential areas for improvement, set measurable goals, and monitor the effectiveness of change. It’s important to collect baseline data before beginning a QI project, commit to regular data collection, carefully analyze your results at the end of the project, and make decisions based on your analysis.

- Communicate results. Quality improvement does not exist in a bubble— your QI efforts will affect your team members. As you plan and implement a QI project, communicate project needs, priorities, actions, and results to team members. When a project is successful, celebrate and acknowledge that success.

- Commit to ongoing evaluation. Quality improvement is an ongoing process. A high-functioning business will strive to continually improve performance, revisit the effectiveness of interventions, and regularly solicit team member and client feedback.

Metallurgy

Metallurgy

Our team of Metallurgists collaborate with metal companies in the United States, Europe and Asia. This specific consulting service provides decades of experience to metal forging and casting companies, assisting to minimize poor metal products during the casting/forging/heat treatment processes, increasing yield and, in turn, revenue and profits. Processes, and formulas are reviewed along with results. Analysis will ensue to identify the problems with the process and solutions will then be provided.

The process used for the extration of metals in their pure form from their ores. The branch of science and technology concerned with the properties of metals and their production and purification. Metallurgy is a domain of materials science and engineering that studies the physical and chemical behavior of metallic elements, their inter-metallic compounds, and their mixtures, which are called alloys. Metallurgy is also the technology of metals: the way in which science is applied to the production of metals, and the engineering of metal components for usage in products for consumers and manufacturers. The production of metals involves the processing of ores to extract the metal they contain, and the mixture of metals, sometimes with other elements, to produce alloys. Metallurgy is distinguished from the craft of metalworking, although metalworking relies on metallurgy, as medicine relies on medical science, for technical advancement. The science of metallurgy is subdivided into chemical metallurgy and physical metallurgy.